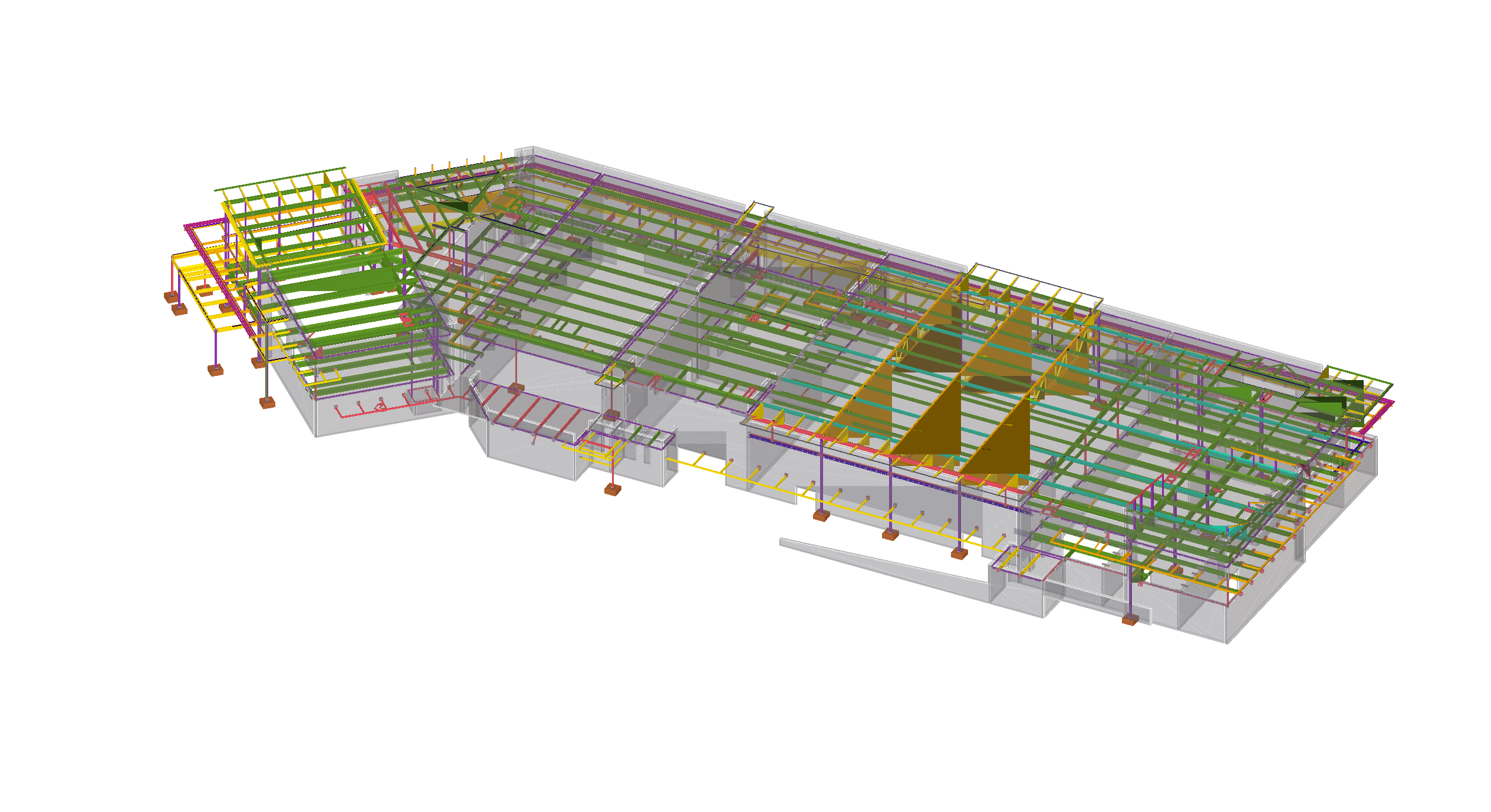

Detailing

Structural and Miscellaneous

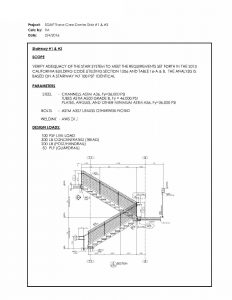

Engineering

Stairs and Connections

Project Management:

We follow good and sound project management principles and guidelines such as weekly reports, conference calls, request for information, follow-up and document control etc. for smooth execution of the project.

Manpower:

Our team leaders are industry veterans and the team members have deep domain knowledge in the respective engineering discipline. Plus our teams are regularly trained in-house and by industry experts that leads to higher productivity.

Infrastructure:

We invest in work place, dual monitors, remote backup, UPS and latest engineering software tools.

Dedicated Team:

We retain and make available the services of the same project team so that client expectations are met and the learning curve is minimized and consistency is greatly improved.

We analyze, evaluate, organize and communicate a plan of execution for a project's scope of steel work.

This would result in the following:

- Anchor bolt setting plans and details.

- Erection plans.

- Shop drawings and bill of materials of all structural steel members.

- Detailing of all miscellaneous steel, stairs, railings, ladders, ducts & platforms.

Ability to supply Production Tracking Reports: ABM's, Shop Bolt Lists, Field Bolt Lists, Material Summary, and Gather Sheets for convenience in the fabrication and erection process.

Capability to provide CNC, KSS, DXF, CIS2, IFC, and VRML files for Material Management software systems, shop production line equipment or merging our model with the final construction model for clash detection

Proficient project management is one of our unique strengths. We have structural steel project managers that work with each client to ensure that projects run smoothly. They communicate effectively, interact with the client's team, manage workflow, handle RFI's and deal with deadlines.